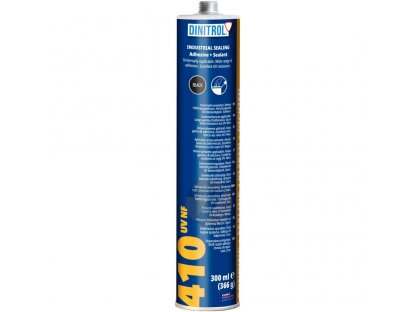

Polyurethane adhesive - sealing compound 300ml / 366g extrusion cartridge

Dinitrol 410 UV 1K Polyurethane Klebe- und Dichtungsmasse 300 ml, 1 Component polyurethane sealant and adhesive 300 ml

Characteristics:

DINITROL 410 UV is used for structural bonding and sealing in the automotive industry (superstructures, cabins, etc.), in service and many other areas. It is intended for normal stressing of the glued joint. The usual color range (black, gray and white) is available.

DINITROL 410 UV has a high stability of properties, including resistance to UV radiation. It hardens quickly and is elastic in its final state. It has excellent adhesion to most substrates. For structural bonding, it is recommended to also use subsequent auxiliary materials, see below. Depending on the circumstances, some operations may be omitted during sealing.

A full working procedure is a guarantee of the quality and service life of the glued joint. Application is simple using the usual aids and tools. The adhesive has very good shape stability after application (in an unripe state), forms only a short "hair" and quickly ripens due to air humidity.

DINITROL 410 UV can be overcoated with most coating systems. Repainting of flexible joints should be done using flexible paint systems to prevent paint cracking. Immediate repainting - wet to wet - with 2K acrylic varnishes is possible. This does not apply to paint systems containing alcohol or alkyd resins or Substances that would interfere with the curing process.

Fields of application:

DINITROL 410 UV is used for bonding and sealing in various areas, such as in the production of buses, trucks, caravans, rolling stock, ships, etc. Application is possible in a number of other industries.

DINITROL 410 UV shows very good adhesion both on basic materials and on painted surfaces, plastics, glass laminates, wood, glass and many other substrates. To verify full adhesion, we recommend performing an adhesion test before permanent use.

DINITROL 410 UV is suitable for indoor and outdoor applications for bonding overlapping joints, roofs, decorative and protective strips, etc. It is also well suited as a repair material for bonding and sealing. We also supply DINITROL 600 and F 500 for strength joints with peak stress.

Application:

In the case of the application of DINITROL 410 UV for sealing structural elements, it is possible to omit some steps from the below-mentioned technology after testing.

Preparation of surfaces for gluing:

- clean the glued surface with a general grease cleaner (e.g. DINITROL 7250)

- clean the surface mechanically with Scotchbrite or sandpaper from mechanical impurities and oxidic layers (Flex sander and blasting, etc. are also used)

- further prepare the cleaned surface using the DINITROL 520 KLEENACT system, apply and wipe and let it "ventilate" for approx. 5 minutes (depending on the absorbency of the substrate)

- apply the base layer DINITROL 550 UNIPRIME (several increase in adhesion and anti-corrosion protection) and let it dry for approx. 30 min.

For special cases, clear primer DINITROL 560 PVC PRIME or next. Then apply glue to the prepared surfaces and assemble the assembly before "skin creation time".

It is advisable to use spacers to ensure the correct strength of the adhesive after hardening, which should be at least 2-3 mm. Where the initial adhesion of the glue is insufficient, fix the assembly mechanically.

If you are gluing to the original bead of glue (during repairs), then just before gluing, cut it with a chisel to a thickness of approx. 1 mm and apply polyurethane directly. Do not use either DINITROL 520 KLEENACT or DINITROL 550 UNIPRIME on the polyurethane layer cut in this way!

General principles:

- Processing temperature from +5°C to max. +35°C.

- The glued parts and the materials used must be at the temperature of the workplace so that there is no condensation of air humidity during the gluing.

- DINITROL 550 UNIPRIME contains settling solid particles and must therefore be thoroughly mixed before use using the included mixing balls.

- Unhardened glue can be removed with white alcohol and shaped with DINITROL 300. Hardened glue can only be removed mechanically.

- All materials used are hygroscopic (they absorb moisture from the air) and for that reason the packaging must be closed immediately and stored in a dry place.

- The manufacturer guarantees a perfect gluing result only when using the complete DINOL gluing system (KLEENACT, UNIPRIME and follow-up glue) and following the application procedure see earlier.

- The handling strength of the joint depends on the temperature and atmospheric humidity after 2 hours, outside of the groups that are mounted with pretension.

Technical data:

Black colour

Base: polyurethane pre-polymer

Density (at 20°C): 1.26 g/ml

Fluidity (at 2.6mm/2.8 bar 20°C) 45-60 g/min (from cartridge)

Processing temperature: +5 to +35°C Temperature resistance: -40 to +90°C (short-term up to 120°C)

Solidification - ripening: through air humidity (r.v.)

Skin formation time: approx. 25 min at 23°C and 50% RH. humidity

Non-sticky: approx. 2.5 hours depending on the conditions

Curing (23°C, 50% r.h.): approx. 3 mm in 24 hours

Hardness-Shore A: >40

Relative elongation (DIN 53504): >600%

Shear strength

Cookie - Settings

Cookie - Settings